- Mon - Sat 8:00 - 6:30, Sunday - CLOSED

- Plot No. 1409 Phase III, G.I.D.C. Vatva Ahmedabad - 382445

Previous

Next

BMM Engineers follow AS ME / IS / API, BS, cGMP Code, or other codes available in the nternational Market to suits the customer requirements for applications. BMM Engineers specially Agitator design on the following Chemical Processes:

- Hydrogenation

- Esterification

- Oxidation

- Brominating

- Homogenization

- Slurry Preparation

- Chlorination

Equipment's

- High Pressure Autoclaves

- Hydrogenator

- Jacketed Reactors

- Limpet Coil Reactors

- Homogenizer

- Agitators (As per Process Requirements)

- Pharma Kettles

Design Capacity & Range

- Capacity Range: 250 Ltr to 100KL

- Shell Diameter: up to 5000 MM

- Pressure Range: up to 120Kg/cm2(g)

- Temperature Range: -80°C to 350 °C

Special Features of Reactor

- High heat & Mass transfer area

- Cutting down Batch Cycle Time

- Low power consumption

- Capacity Expansion

- High mixing efficiency

- Cost Reduction in Process Operation

Type of Mixings

- Liquid-Liquid Mixing

- Liquid-Solid Mixing

- Gas-Liquid Mixing

- Gas-Liquid-Solid Mixing

- Homogenisation

- Wet Grinding

Application of BMM Engineers specially designed Impellers

- Hydrogeneration

- Oxidation

- Homogenization

- Chlorination

- Esterification

- Bromination

- Slurry Preparation

Materials of Construction

- Different Grades of Stainless Steel (SS304 / SS316 / SS316 L / SS316Ti / SS317 /SS321 / SS904L)

- Duplex and Super Duplex Stainless Steel

- Hastelloy – C (C22/C276)

- Titanium

- Monel400

- Carbon Steel (CS/LTCS)

- Clad Material

- Aluminium

- Nickel Alloys

- Lined with special non corrosive material like PFA, TEFZEL, HALAR, Rubber lining, etc.

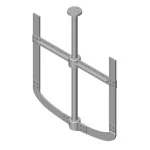

Type of Agitators

BMM Engineers

Purchase Department:

Admin Department:

- © Copyright 2022 by BMM Engineer's Industries All rights reserved.